- Availability: Out Of Stock

- Made & Mkt by: Paresh Patel

- Product Code: 4544-RB20-17

- Weight: 650.00g

- Dimensions: 621.00cm x 113.00cm x 0.00cm

The typical dispatch time is 2-3 days; however, in special cases, it may take longer. Please refer to the product details section for specific timelines. Once dispatched, we will share the tracking details with you.

For returns, you can file a request within 24 hours of receiving the product. If the package is damaged, please make a video while unboxing and share images of the damaged item along with your return request.

Patola is an exquisite and wonderfully intricate silk textile of India, believed to have originated in the 7th Century AD. Patola silk textiles are produced by resist dyeing of warp and weft threads before weaving, a complex process known as double ikat which is also practiced in other parts of India and abroad. However, Patola of Patan (Gujarat) is unique in its geometric floral and figurative patterns executed with precision of design planning, and meticulously accurate weaving alignment which results in precise outline of the patterns. This requires immense visualization and coordination skills. It is a marvel of weaving and precision, with its many coloured warp and weft matching perfectly at their designated places to create intricate motifs.

A precious piece of heirloom, passed down through generations and preserved to be brought out only for the most important occasions, the Patolu, or Patola is one of the most prized and valued textiles.

A breathtakingly beautiful variant of the same was introduced in the weavings of Gujarat when the popular zari brocade weaving was combined with it. The sarees thus produced came to be popularly known as ‘Amdavadi saree’ or after the name of the early ‘pore’ (neighbourhoods in Ahmedabad were called pores) , Assaval it was practiced in till 1980s, it was given the name of ‘Ashavali’ by the Lalbhai family first. Assaval was the hub of old brocades in Gujarat at the time and they were immensely experimented in. From fabric construction (plain, twill) to material (kora cotton, silk, khadi, silk-cotton, cotton-cotton) to combining techniques, everything was tries.

One of the very few units of Ashavali today is placed in the village of Ridrol near Ahmedabad. Somabhai Gigidas, a farmer set up a Jala loom in his house to start weaving as a part time occupation. Till 1985 the set up increased to 10-20 looms and rose in coming years to a lavish layout of about 100 looms active and producing Ashavalis. The looms also changed in this time from the old Jala to Jacquard setups. Today, his third generation Paresh Bhai, operates from his studio in Ridrol with about 50 looms and 98 master weavers. They experiment with weaves, dyes, develop new motifs and also revive old motifs from the archives. The width of the saree woven varies interestingly from 45” to 47”. Paresh bhai explains this change as the need of the time, since the average height of the women wearing sarees has decreased.

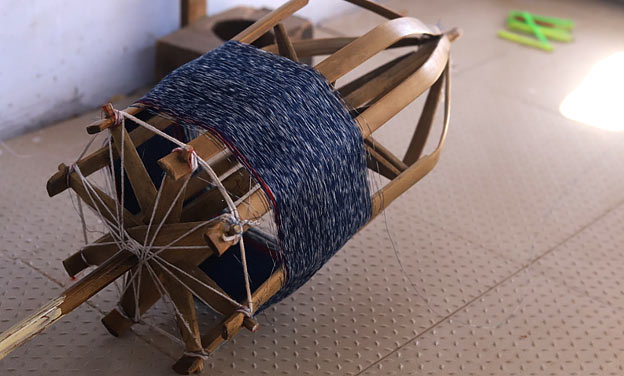

The first step in making a Ashavali is tying of the yarn with cotton thread according to the pattern just like Patola. The tying of yarns is an intricate and time – consuming process, with measurements as small as 1/100th of an inch. Natural, Azo free dyes are used. The yarn undergoes multiple cycles of tying and dyeing, following a specific order of colors. The yarns have to be carefully arranged during and after dying, as displacement of even a single yarn can disturb the design arrangement and render the entire set of yarns useless.

Post dyeing, the yarns are stretched out to make the warp. The warp in this case is specifically Mulberry Silk, the weft may change. This requires the presence of a master craftsman, as repairing the broken threads and arranging the warp requires a great deal of experience.

The loom is one of its kind in many ways. It is a pit loom with minor variations, tilted to one side and requires two people to sit and work together on one sari. The rosewood sword shaped stick called “Vi”, which is used for adjusting the yarns, is also specific to the loom. Zari and Silk come from Surat, variants range from Rs 6000/kg (98 silver) to Rs 80000/kg (gold plated).

Every colour in every yarn has its own unique place in the sari and it has to be carefully aligned with the pattern while weaving. After every few inches of weaving, the design is adjusted using steel needles. A close view of weaving shows the intricacy of the design with each of the thread having its own place in the fabric. Two people have to work together on the loom and it can take a month or even more, to make one sari. Jacquard set up however helps in weaving faster with average of 2 sarees a month. The binary code of the Jacquard cards is individually made for every unique design and these cards were personally punched by his father at the time.

Each of the motifs and colours have different significance in different communities. The elephant (kunjar), flower (phul), girl (nari) and parrot (popat) designs are very commonly used motifs in saris worn by Gujarati women and the elephant and tiger motifs are considered particularly auspicious. The Pan Bhaat (Leaf Design) is one of the most frequent patterns. It is a motif indigenous to India and can be traced back as far as the pottery of the Indus Valley culture. Some other revived motifs include Tilfi Buta, Chand Buta, Pankha border, Cut Meena etc.

The cloth derives it’s magic from the purity and sheer genius of construction, which is inferred from the material; silk, it’s natural dyed yarn and also from the fact that it was designed by members of the higher Hindu and Jain communities. Certain motifs are considered to be auspicious to ward off evil. A dash of sheen extended by the inclusion of zari brocade adds sparkle to the act of magic. Therefore, it is hardly surprising that these textiles play an important role in religious and social ceremonies.

Today, the craft survives scarcely in the face of many threats like; high investment of time and money, low returns, and lack of interest for continuing the craft among the younger generations. And even though the current generation of craftsmen are willing to work for the next few years, there aren’t any new people taking up this profession.

| Craftsmen | |

| Made by | Artisan working with Paresh Patel |

| Returns and Exchange | |

| Note | -With Blouse -The items in this category cannot be returned or exchanged. The products in this category is handmade. These might slightly differ from as seen on digital screen. |

| Material | |

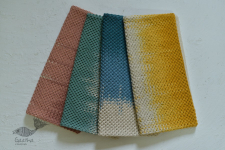

| Made of | Pure Silk & Zari | Natural Color |

| Instruction | |

| Instruction | The product is hand woven; gentle hand-wash or dry clean is recommended. |

-550x550w.jpg)

-550x550w.jpg)

-550x550w.jpg)

-550x550w.jpg)

-550x550w.jpg)

-550x550w.jpg)

-550x550w.jpg)

-550x550w.jpg)

-80x80w.jpg)

-80x80w.jpg)

-80x80w.jpg)

-80x80w.jpg)

-80x80w.jpg)

-80x80w.jpg)

-80x80w.jpg)

-80x80w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

/01_03_2024/Gond-Art-Hand-Painted-Gond-Painting-4-X-5-Feet-Three-Tigers-225x150h.jpg)

/01_03_2024/12-2-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-250x250w.jpg)