- Availability: 1

- Made & Mkt by: Dhani Ram Soni

- Product Code: 4019-B22-OCT-12

- Weight: 850.00g

- Dimensions: 40.00cm x 40.00cm x 20.00cm

The typical dispatch time is 2-3 days; however, in special cases, it may take longer. Please refer to the product details section for specific timelines. Once dispatched, we will share the tracking details with you.

For returns, you can file a request within 24 hours of receiving the product. If the package is damaged, please make a video while unboxing and share images of the damaged item along with your return request.

Bundele har bolo ke muh humne suni kahani thi ….. Lights cascading from fountains of oil lamps suspended from the high ceilings of the palace, spill into the distinguished ambience and light up the regal conversations between aristocrats. Some Conversations are punctuated by sips off the ‘hookah’, some others by intermittent chewing of the ‘paan’. Royal dialogues like these are mummified within layers of opulence and luxury. …and some of these layers get exposed through curious articles of the bygone era as few royal whispers discreetly leak out. The lost wax technique is one such similar layer, reminiscent of the glorious lives of the Bundelas of central India that reveals the indulgences of a celebrated era.

Bundelkhand was ruled by the Chandela rulers until 16th century. Today the region remains divided between Uttar Pradesh and Madhya Pradesh with the larger portion in the latter state. Folklore has it, that Virbhadra, the ruler of Kasi [present day Varanasi] had two wives. The elder wife had 3 sons & the younger just one – Jagdas (also known as Hemkaran). When the king died, the sons of the elder queen refused the young prince his share of the kingdom & instead sent him into exile. As a wanderer, he traveled into the mountains of the Vindhyas to worshipVindhyavasini Devi (the Goddess who dwells in the Vindhyas). Extreme penance brought no response from the Devi, so in desperation, the prince drew out his sword to behead himself. When the steel drew the first drop of blood from his throat, the Devi appeared & said that she was so pleased with his courage & devotion that she blessed the sword he carried and turned the drop of blood into a boy who she said would be destined to become the founder of a warrior clan known as the ‘Bundelas’ – [the givers of the drop – of blood].

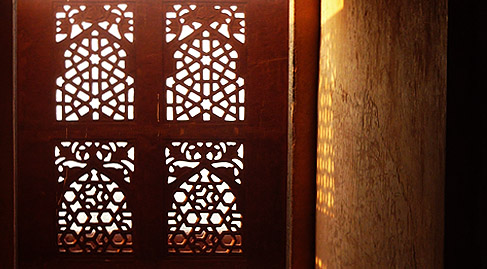

And as blood turned into fighter folk, the state of craft reached a level where wax almost turned into metal. The fine web of latticework on these artifacts, eloquently suggest the ‘jaali’ and ‘jharokkha’ patterns that are peculiar of the native palace architecture. Forms, which enshrine the memory of lost wax within the body of casted metal, are ingenious to the creative soil of this land and intuitively assume an aesthetic so divine and rustic, that it appears as if the gods have forgotten to carry these little brass beings with them when they were leaving the earth.

This 500 years old craft has historically been a forte’ of goldsmiths coming from the clusters of four prominent regions of Bundelkhand i.e Tikamgarh, Gwalior, Datia and Jakora. The technique of lost wax casting pursued in these regions was primarily of two categories. The silver/gold ornaments such as Gujari, payal, Pejnak, kada, toda (meant to be worn in the feet and arms), kakana, chani, kamarbandh and others, with popular motifs inspired by nature, architecture (now done in whitemetal popularly known as German silver).

These ornaments are associated with popular local myths .For instance ,the weight and form of these ornaments can apparently relieve the acupressure pints on the body.The second category on the other hand, includes idols of gods and goddesses, hukkas, paandaan, kalash, sandook and various objects of daily utility.

And the utility based objects in gold and silver. These include idols of gods and goddesses, hukkas, paandaan, kalash, sandook and an entire range of collectables that have quenched the royal thirst for luxury since ancient times (now made with brass, locally known as bell-metal).

Native craftsman Lakshmi Narayan Soni observes that due to the very antiquated appeal of the final product, it is only the connoisseurs of art and artifact lovers who are particularly fascinated and end up buying them as objet d’art. But they are making conscious attempts to enhance the functional convenience of these by making minor manipulations in the original piece, without altering the aesthetic intent. An extremely heavy anklet for instance has been converted into an ash-tray by addition of a metal plate over the open side, so that it assumes more practical relevance in the same opulent avatar.

The raw materials required for the lost wax technique include bee’s wax, oil, clay gasses cow-dung cakes, earth, sand, dhariya (to melt the metal) and wood.The non-natural raw materials are sourced from Gwalior. The tools required to execute the technique are dhatiya (wooden bat), patla(flat wooden surface), athali(wooden sculpting and molding tools),small and big chisels, hammers and tongs.

The wax is prepared over a period of 2 days by melting and repeated heating. A mixture of cowdung and clay is used to create a mould. Intricate designs are made by making wicks of wax and arranging them along the detail of the pattern.

Over this, a clay-based paste is applied to an extent that it percolates into the voids of the pattern. Another thick coat of clay mixed with sand is then applied externally over the form. This last coat involves application of clay and sand (bajari). Here, the sand act as strengthening agents and prevent the mould from breaking open when heated. This is then kept in sun till it dries.

When the mould is heated, the wax begins to melt and is poured out through a hole left open while it was made. Molten Bell metal or brass is then poured into the cavity rendered empty by the lost wax. This non-ferrous metal casting takes over 15-20 minutes to complete. The external covering of clay is then wiped away, but the clay that is trapped within the metal body ends up staying that way till the end. Sun drying is essential else, the entire piece may become more prone to damage. Sanding and polishing result in final finishing.

A single piece requires up to ten days to come to its finished form. Even though the commercial corridors are flooded with tailor made moulds, one cannot find a parallel synonym of the intricacy that flows out of a traditional piece made by the bell-metal craftsmen of MP. The play of convoluted solids and voids that gracefully perform an impressive ballet over organic metallic contours is a memorable metaphor that can never be imitated.

| Craftsmen | |

| Made by | Dhani Ram Soni |

| City | Datiya, Madhya Pradesh |

| Material | |

| Made of | Brass |

| Instruction | |

| About Sizes | 6.5x6.5x5.5 cms. | Weight - 225 Grm. |

| Note | As each piece is handmade and unique, please expect a slight variation from shown design. |

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)