- Availability: Out Of Stock

- Made & Mkt by: Vividh By Fabrics Of India

- Product Code: 4027-G-HPB-15

- Weight: 350.00g

- Dimensions: 610.00cm x 112.00cm x 0.00cm

The typical dispatch time is 2-3 days; however, in special cases, it may take longer. Please refer to the product details section for specific timelines. Once dispatched, we will share the tracking details with you.

For returns, you can file a request within 24 hours of receiving the product. If the package is damaged, please make a video while unboxing and share images of the damaged item along with your return request.

9328006304 ( WhatsApp )

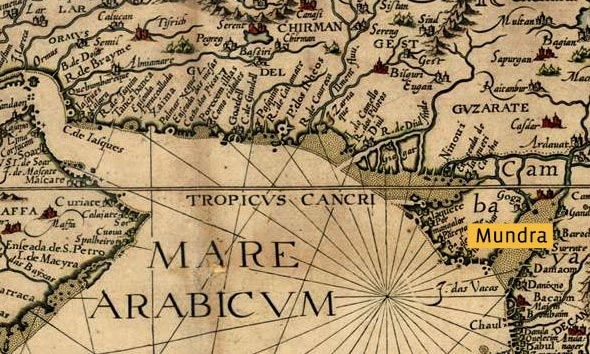

Lying in the western frontiers of India, the Gujarat province with its 1600 km long coastline has been the centre for international trade since ancient times. The trade vastly depended on agricultural produce and products of fine craftsmanship, port of Mundra being one of the major stops during ancient and medieval period. Archeological Evidences reveal existence of strong trade relations between the port of Mundra and ports in Arab and Egypt along the Red sea. These goods were further transported to Europe through Mediterranean Sea. Until 1969, the port was still used by Haj pilgrims to commence their sacred journeys.

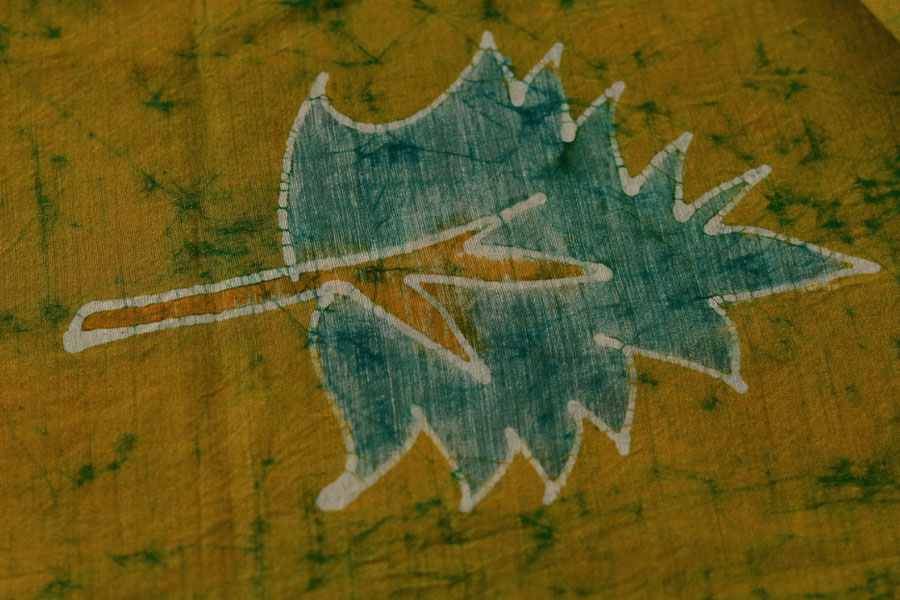

Due to flourishing trade in this coastal town, people from various communities and regions started inhabiting here. Amongst these were some of the craftsmen communities that saw great trading potential for their products, Batik printers being one of them. As a result, the town of Mundra had some of the finest Batik workshops.

Batik prints were an essential part of the daily ensemble of the native communities, the artisans made ‘Odhna’ (90’’ X 90’’) for women with Fulkiya print, Bairaj print, Singh Champa print and Chonia print. It was made by stitching two length of fabric side by side and each community had their own preference of motifs. Khatri community women wore Batik Salwars, which were hand-stitched by them. As for men, they used to wear batik printed ‘mediya rumaal’ ( kerchiefs) as turbans.

There was a time when Mundra and Bhujpur (village near Mundra) were known for their Batik. The Mundra family of Batik artisans once comprised of sixty-six members and all of them were involved in carrying out the process. With the arrival of industrially produced colorful alternatives, the craft faced an unjust competition and consumption gradually decreased over the years. The new generations moved on to more lucrative livelihoods and the workshops stopped printing fabrics in 1960. Then again in 1961, a couple of enthusiastic artisans began reviving this native craft. Presently, the traditional batik fabric can only be found in the local market at kutch or at very few shops in Ahmedabad, as only a few families could continue with this craft.

Today, there are 4-5 Batik workshops in Mundra. The process starts with removal of starch from the plain white fabric. The fabric is soaked in soda and with thorough rinsing; the starch from the fabric is removed. A work table is prepared by spreading river-bed sand on a long rectangular surface. The printer begins block-printing with wax once the plain fabric is laid out on the table.

The fabric is dyed after the printer is done with the first phase of wax printing. Post-dyeing, the area covered with wax retains the base color, while rest of the fabric attains the dye color. Number of stages of printing and dyeing depends upon the design and colors involved. When the whole printing process is completed, the process is concluded with subsequent washes in warm water. The wax melts and it is collected in a separate container. Thereon, the fabric is sun dried. Each fabric is about 10 metres in length. These are rolled and stacked in the warehouse.

It is the fifth generation of artisans practicing the craft in Mundra. Amongst the present generation of printers, Shakeel Ahmed Khatri continues to work as a pioneer towards the revival of the craft and his work has received appreciation across the world. To keep up with the heavy demand, Shakeel says “Mundra artisans are using Parraffin wax these days (earlier beeswax was used for printing ), which is sourced from China.” Around 75% of the wax used for printing is reclaimed and used again.

For dyes, the artisans use reactive and napthol dyes which are derived chemically. The artisans find it difficult to use traditional natural dyes such as alizarine, rust, turmeric, indigo etc. as they react badly with paraffin wax; they are still searching for the alternatives to paraffin wax, so that the whole process can be made organic and sustainable again

.

These Batik workshops of Mundra are grounds of interesting conversations between people, their stained hands and the long stretches of fabrics, between resistive wax and persuasive dyes. The emerging patterns hold within them the very proof of these conversations, the tales of resistance, perseverance and acceptance.

| Craftsmen | |

| Made by | Artisan working with Vividh By Fabrics Of India |

| Returns and Exchange | |

| Note | ♦ Imperfections and variations in the product cannot be termed as defects, as these are intrinsic to the handmade process. ♦ These might slightly differ from as seen on digital screen. |

| Material | |

| Made of | Maheshwari Silk |

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-225x150w.jpg)

-234x234.jpg)

-234x234.jpg)

-234x234.jpg)

-234x234.jpg)

-234x234w.jpg)

-234x234w.jpg)