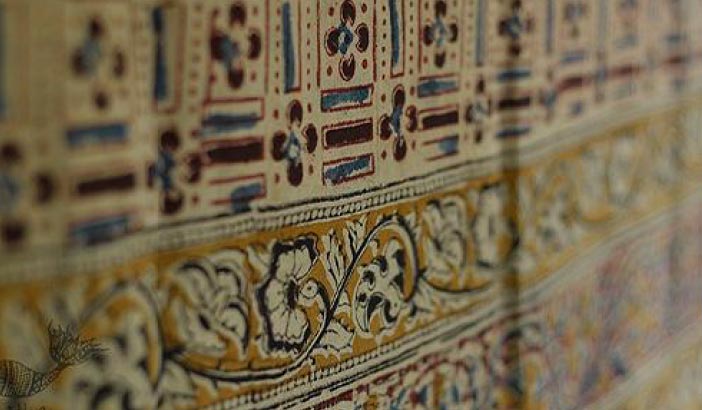

Famous Block printing art across India, the printing technique of stamping fabrics using carved wooden or metal blocks dipped in dyes is an ancient craft that India can boast about. Whether it is Gujarat’s Ajarakh, Rajasthan’s Dabu, or Madhya Pradesh’s Bagh print, this ancient labor-intensive art form has not lost its charm even today. Even though block printing originated in China around 4,000 years ago, India adopted and built the art form even further. Each block print represents India’s vast legacy and rich culture. India is one of the largest manufacturers and exporters of block-printed fabrics.

1. SANGANERI PRINT - From sophisticated printing & dyeing techniques for the royal attire to floral depictions across usable & temple textiles; Sanganeri block printing dates back to the social upheavals of the mid-17th century when Gujarati printers fled to the Dhundhar region of Rajputana, now known as Rajasthan. Centuries-old, the Sanganeri hand printing technique originated in the village of Sanganer, located in the southern part of Jaipur, Rajasthan. The continuous wars between the Mughals and the Marathas caused numerous crafts workers to migrate from Gujarat to Rajasthan, finally finding a retreat in Sanganer. It has been thriving since then. During British India, this craft became one of the major export items for the East India Company. This antique craft consists of a great variety of designs and patterns. It includes all kinds of flower motifs, designs depicting gods, fruits, folk tales, delicate patterns, lines, and vibrant colors. Sanganeri artisans may use chemical and vegetable dyes. They commonly utilize a method called ‘calico printing’. This involves printing of outlines and subsequently filling of the colors. Artisans typically repeat these designs in diagonal sections. Another famous method of block printing is “doo-rookhi”, in which the fabric is printed on both sides.

2. BAGRU PRINT - The traditional printing technique of Bagru is practiced by the ‘chippas’ community in a village in Rajasthan. Usually done on blue or indigo backgrounds, seyali bagru prints and dabru prints are two popular kinds of prints. The seyali bagru printed fabrics are famous for their distinguished black and yellow/ochre combinations. On the other hand, Dabri prints are created using a special resist technique where the print is hidden from the dye. Predominantly the pattered and motifs in Bagru prints are geometrical, usually circular. They are combined with floral and fauna motifs to create appealing designs.

3 . DABU PRINT- An assortment of deep earthen tones and magnificent prints, 'Daboo' or ‘Dabu’ is an olden Rajasthani mud resist printing technique known for displaying subtle depth. Believed to have originated in China, back in 675 AD, this technique traveled to Rajasthan. It started blooming in the Village of Akola. Like the craft, the raw materials are also timeless – mud and water. Replenished generously by nature, these are believed to have been employed in India, during the 8th century AD. This is indicated by the oldest specimen found of Dabu printed fabric in Central Asia.

Having almost died in the last century due to the prevalent alternatives, Daboo printing was revived by its artisans. Today it is flourishing across the globe. The designs and motifs in Dabu printing are inspired by natural alignments

like flora, fauna, and artistic ethnic motifs. A painstaking and labor-intensive process, Dabu printing starts with soaking the fabric for around 24 hours and washing the fabric to clear away all impurities from it. Wooden blocks are then dipped in natural dyes and hand-printed on the fabric. Sawdust is sprinkled on top of the fabric to avoid any smudging. A mixture of gum, lime, and white chaff is prepared. It is then applied to the fabric and dyed. Once dried, the fabric is dipped in dye and then washed to remove excess dye and paste.

4. AJRAK- A king once grew so fond of his bedspread that he insisted his maids to let it stay on his bed for one more day, he muttered “aj ke din rakh”, the phrase which went on to be used to name that uniquely printed fabric as Ajrakh. It is also believed that the fabric derived its name from the Sanskrit word ‘A-jharat’ or ‘that which does not fade’. ‘Azrak’, the Arabic word for blue could have also played a role in its etymology because of the extensive use of indigo in the process. Ajrakh originated in the provinces of present-day Sindh in Pakistan and the neighboring districts of Kutch in Gujarat and Barmer in Rajasthan. Although Ajarakh printing is a part of Sindh, during the Indus Valley Civilisation, its roots extended to the states of Rajasthan and Gujarat in India. The Indus River proved to be an essential resource for washing fabric and acquiring raw materials like indigo and cotton along the river. The ingredients are all obtained from nature- from herbs, vegetables, and natural minerals. Camel dung is used as an ingredient to remove stretch from the fabric. The natural dyes used in Ajrakh printing expand the pores of the fabric during summers, making it easier for air to pass through. During winters the pores of the fabric close, proving warmth.

5. GAMTHI PRINT- Gamati print originated from the humble villages of Gujarat and Rajasthan. Gamthi print uses vibrant and bold colors and varied, intricate patterns. Elements used in this technique are mainly inspired by nature. Initially, natural dyes were used, but today they have been replaced by chemical and artificial colors. The main colors used were, green from henna, yellow from turmeric, blue from indigo, and black from rusting iron, about 27 different colors could be achieved through plant parts and metals. Made of seasoned teak wood, blocks are the main tools of the printer. With designs etched on the underside and two to three cylindrical holes drilled vertically and horizontally across the body of the block, the block makers of Pethapur ensure free air passage and release of excess printing paste, making their blocks so special.

6. KALAMKARI- One of the earliest and most complex block-printing techniques, Kalamkari grew in Masulipatnam in Andra Pradesh. The word originated from the words Kalam, meaning pen, and Kari meaning Work. Kalamkari is an amalgamation of painting and hand printing. This craft originally started in the city of Golconda after which it spread up to the eastern coast of Tamil Nadu. Kalamkari was born out of the art of story-telling by using rich & classic colors to portray stories from Ramayana and Mahabharata. Common motifs drawn are flowers, peacocks, paisleys, etc. The Kalamkari fabrics are well known for their beautiful designs on carpets, bed sheets, wall hangings, sarees, table clothes, and curtain clothes and were once traded to Europe and Gulf against gold. Some of the ancient Hindu-mythology-inspired Kalamkari themes were later modernized by craftsmen as the demand for Kalamkari in the international market started increasing. Thus, a Persian influence slowly crept into the original Kalamkari designs

8. BATIK PRINT - It is an ancient art that uses wax and dyes to create magical prints on fabrics. Birthed somewhere in the Middle East, Egypt, and parts of Asia, Batik uses tie and dye methods using wax to create alluring patterns. The process starts with the removal of starch from the plain white fabric. The fabric is soaked in soda and with thorough rinsing; the starch from the fabric is removed. A work table is prepared by spreading riverbed sand on a long rectangular surface. The printer begins block-printing with wax once the plain fabric is laid out on the table. The fabric is dyed after the printer is done with the first phase of wax printing. Post-dyeing, the area covered with wax retains the base color, while the rest of the fabric attains the dye color. Several stages of printing and dyeing depend upon the design and colors involved. When the whole printing process is completed, the process is concluded with subsequent washes in warm water. The wax melts and is collected in a separate container. Thereon, the fabric is sun-dried. Each fabric is about 10 meters in length.

9. NANDNA PRINT - Nandna is a mud resist block-printing craft of Madhya Pradesh and is one of the very few crafts being practiced in its original form. The fabric thus printed is then worn by the women from the local Bhil tribes as their traditional attire. But what sets Nandna prints apart from the other printed fabrics is its intact rustic look and ancient motifs, equally revered by the contemporaries. When the fabric is immersed in Harda solution, it gives a cream-yellow color to the fabric and acts as a mordant for the alum paste. The cloth is spread out on the table. The printing blocks are dipped in the alum paste and then pressed onto the fabric. The fabric is then dried in the sun. The fabric is boiled in ‘Alizarin’ and ‘Dhawdi ka phool’. The Dhawdi flower keeps the red color of ‘Alizarin’ from spreading into the printed alum. After it is boiled, the fabric is taken out and dried without washing. Once the fabric dries, it is dipped into a solution of gum and water. This helps in the color fastening. Next step is to print with mud. The mud printed areas are smeared with wood dust. This also increases the adhesive strength of the Dabu. This is a cold dyeing process where the cloth is dipped in the indigo dye solution.

Leave a Comment